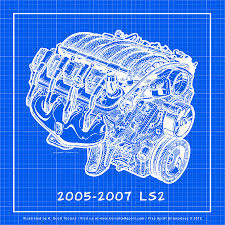

Engine Blueprinting

Blueprinting is an exact science which involves modifying the engine to comply with its original manufacturers design tolerances and/or any newly developed specifications which increase the engines operational efficiency.

|

|

Back in the days prior to the computer age, an engineer would draw an engine design on blue draft paper - hence the name blueprint. The blueprint is the original design specifications of an engine. Blueprinting is an exact science which involves modifying the engine to comply with its original manufacturers design tolerances and/or any newly developed specifications which increase the engines operational efficiency. |

All engines are manufacturered to fall within a range of tolerances which are set by the design engineer on the blueprint. A certain degree of precision can be lost when a vehicle comes from a production line, as there are greater tolerances (a greater range from which the component is measured to compy with) allowed during this process. You may have heard stories where people have bought identical brand new vehicles yet one runs better than the other. The better efficiency and/or performance often means that the engine was slightly better built, i.e. the engine design met the exact design parameters more accurately. Because such a fine line can create a big difference, engines are "blueprinted" to take advantage of the greater efficiency and performance which is able to be achieved.

A standard engine will run perfectly fine operating within manufacturers' tolerances. However, it is an entirely different story for an engine rebuilt for race or performance applications. When rebuilding a high performance engine, it is important to take into consideration, a performance or race engine will be subjected to extreme conditions while it is being operated. The components of the engine need to operate within precise tolerances and measurements to perform this type of operation effectively. Close enough is not good enough. Having the engine meet the exact design parameters with which it was designed and eliminating any discrepancies in tolerances, gives the engine a performance and efficiency advantage.

|

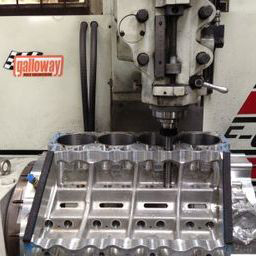

At Galloway Engines, we believe that precision work can only be achieved on quality machines. We have maintained a continuous machinery update policy since 1978 to ensure only the best work is produced. Introducing our Rottler F67A CNC Machine. This machine offers state of the art machining capabilities, specifically designed for high performance blueprinting operations. |

The Rottler F67A CNC Machine blueprinting capabilities include operations such as:

|

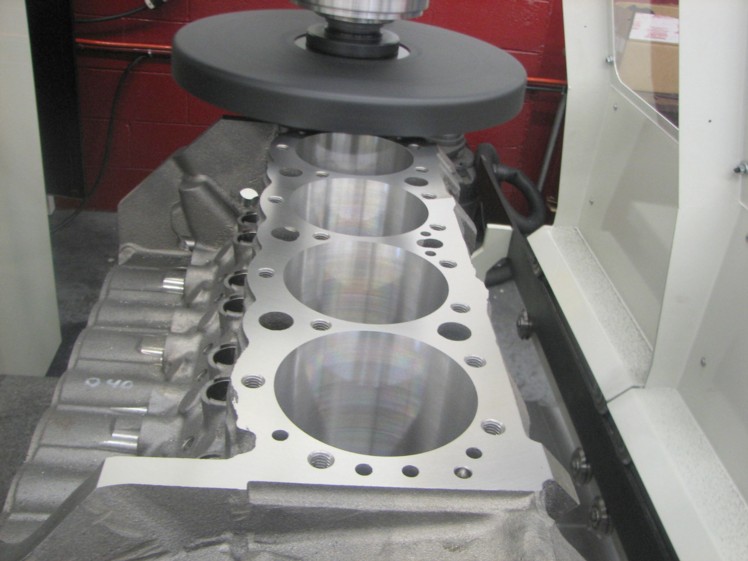

Deck squaring to the main and cam centreline The deck is machined perfectly parallel to the main bore centreline, while correcting any deviations in deck angles. The deck is also height matched, with both decks exactly the same distance from the main centreline. For more information on surface finish, click here. |

|

Boring cylinders to main and cam centreline The CNC boring fixture machines each cylinder bore, not only to the desired diameter, but corrects any alignment issues as well, in terms of bore centreline location and bore angle. |

|

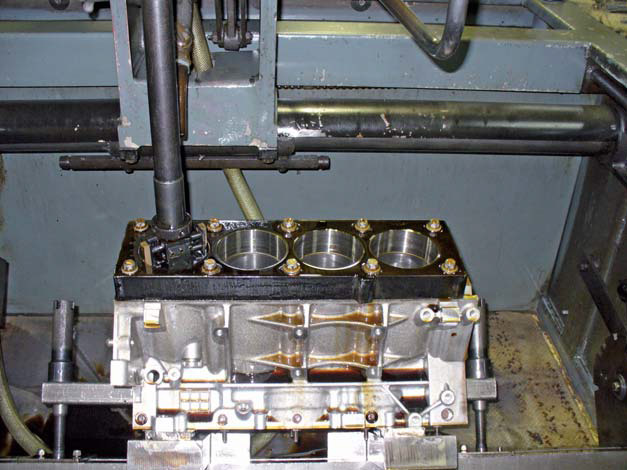

Line boring The patented Rottler right angle drive on the cutting head delivers a more accurate, straighter cut than boring using the traditional boring bar method. |

|

Bore centre corrected to blueprint specifications CNC probing records existing cylinder bore location. This dimension can then be compared to design data, instructing the machine to then bore to correct centerline and angle if needed.

|

|

|

Lifter bore corrections Machining factory lifter bores true to the camshaft centreline can create smoother running and therefore increase horsepower. For more information on lifter bore modifications, click here. |

Galloway Engine's have a fully equipped workshop with machinery which can carry out other blueprinting processes, such as:

| Dynamic Engine Balancing | ||

|

|

See the article "Spin Doctors" for more information on this process. |

| Torque Plate Simulation Process | ||

|

|

For more information on the perfect bore finish, see the article "Finishing Touch" .

|

| Line Bore Honing | ||

|

|

For the perfect finish for the mains tunnel. |

Blueprinting an engine is a detailed process which represents a major investment in your engine. Part selection is critical and it is essential that processes are undertaken to ensure the perfect parts are selected to be installed into your blueprinted engine.

|

Magnetic Crack Testing The slightest imperfection will effect your engines performance and reliability greatly. There is simply no margin for error. This crucial set of conditions requires far more detail than what can be seen by the naked eye. For more information on crack testing, click here. |

|

|

Ultrasonic Testing An engine consists of many inaccessible areas where tools of measurement are simply unable to reach. For more information on ultrasonic testing, click here. |

|

Digital Hardness Testing Aluminium has different chemical properties to cast iron and it is known that it expands and contracts quicker when it heats up and cools down. This quicker cycle of expansion and contraction can cause the material to become stressed. For more information on digital hardness testing, click here.

|

Contact us for more information on how we can assist you to meet your engine performance and efficiency requirements.