Oils For Older Style Engines

As engine technology advances, lubricants and additives are upgraded to run in line with the modern engine and comply with the current environmental regulations.

Oils Just Aren't What They Used To Be

As engine technology advances, lubricants and additives are upgraded to run in line with the modern engine and comply with the current environmental regulations. This means that the latest products released on the market are often not designed for older style engines and do not contain the components or the specifications required by yesterday's technology. This is certainly the case with oils used in flat tappet style engines.

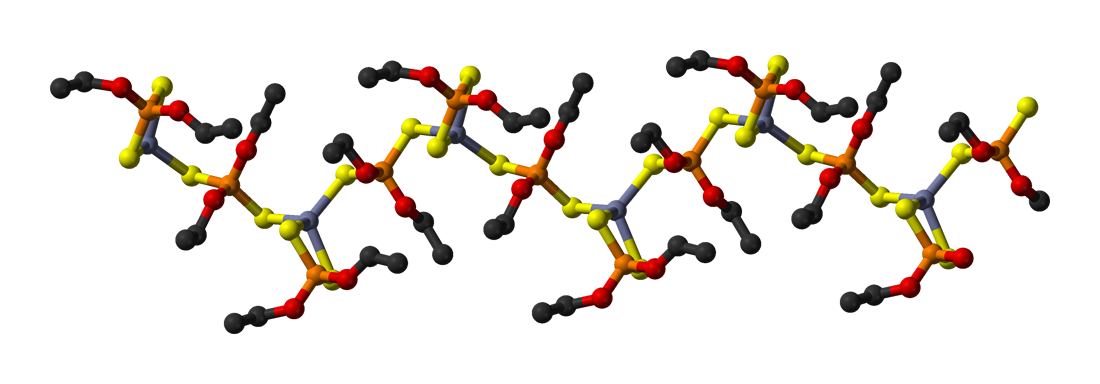

The cam lobe / flat tappet interface is continually subjected to some of the highest pressure loads encountered in an internal combustion engine. Traditional motor oil formulations included a component called ZDP (Zinc dialkyl dithiosphosphate). ZDP offers extreme pressure anti-wear protection. ZDP molecules are attracted to carbon steel surfaces, where they react with heat to create a sacrificial additive coating. This protective coating prevents metal to metal contact, reducing friction wear.

The problem lies with the elimination of ZDP in modern oils. Part of this formulation contains sulfur, in the form of sulfated ash. The ash finds its way into the engine's conbustion chamber and exhaust system, and when combusted, reduces the efficiency of catalytic converters and oxygen sensors. Reduced combustion efficiency increases the potential for dangerous emissions to be released into the atmosphere. This risk prompted the elimination of ZDP from modern oil formulations. As modern engines contain roller lifters, the ZDP anti-wear protection was no longer required as roller lifters do not encounter such high pressure loads.

Modern oil formulations do not offer the same anti-wear protection which older style flat tappet engines require. The result is excessive cam lobe wear and lifter and camshaft failure. This excessive wear resulting from non-use of ZDP typically occurs during the breaking in of a newly rebuilt engine. Of course the best way to overcome this issue is to get the zinc back in. This can be achieved by using either an additive or engine oil supplement, using a camshaft break in lube, or using a traditional engine oil with sufficient ZDP levels. However, it is vital that the recommended ZDP level for your engine is adhered to. It is NOT a case of the more ZDP the better. Once ZDP levels exceed a certain range, the potential for burned ash to accumulate in the ring lands and on piston domes increases dramatically. Ash accumulations in the ring lands can interfere with ring/cylinder wall seal and can cause cylinder wall scoring.

The staff at Galloway Engines can help advise you on the best oil for your particular application to ensure you get maximum life from your engine. Oils just aren't what they used to be!