Fitting Pistons To Conrods

Fitting pistons to conrods would be considered to be a fairly straight forward job for most mechanics. However, it is important that this task is completed correctly.

Fitting pistons to conrods would be considered to be a fairly straight forward job for most mechanics. However, it is important that this task is completed correctly to prevent this from occuring....

|

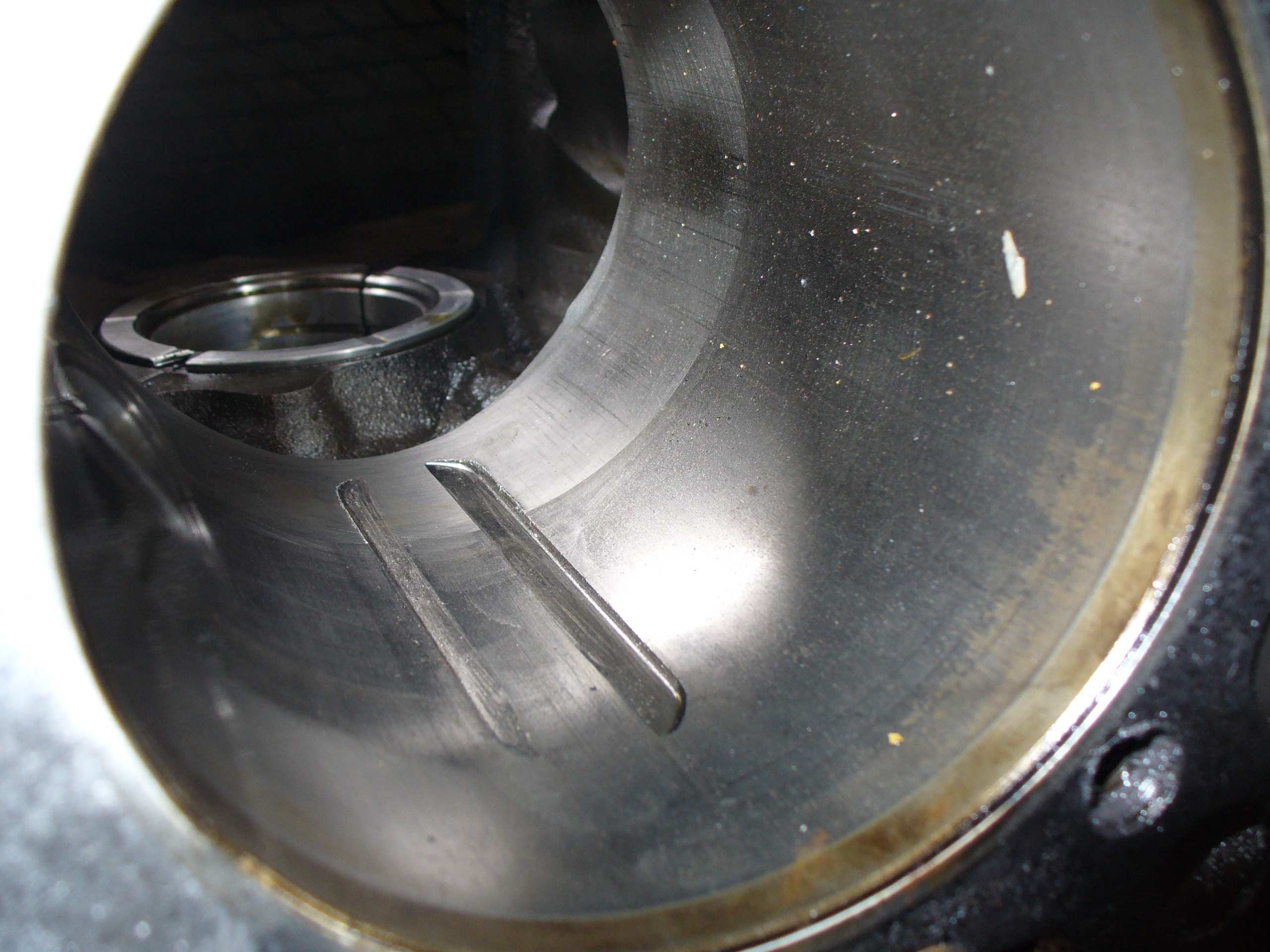

OUCH! These score marks were caused by a loose piston pin. How did it happen? |

By heating the small end of the conrod, the hole expands which allows the piston pin to be inserted. Once it cools, the small end contracts to clamp onto the pin - hence the conrod is fitted to the piston. In this case, an oxy was used to heat the conrod and too much heat was applied.

It is of paramount importance that the conrod is NOT heated too much. When the small end is over-heated, the properties of the metal have the potential to change. The metal can develop elastic characteristics and the small end will not contract back to the same size it initially was. The correct clamping effect does not occur in this situation and hence the pin becomes loose and has the potential to slide out. This is exactly what has occurred in the above example. It is very difficult to control the temperature when using an oxy to heat the conrod. Therefore, this method of fitting pistons to conrods is not recommended.

|

|

Another method of fitting pistons to conrods is to press fit. This however, can broach the small end of the conrod. Once the hole has been enlarged, the piston pin becomes loose and the same problem as above can occur.

|

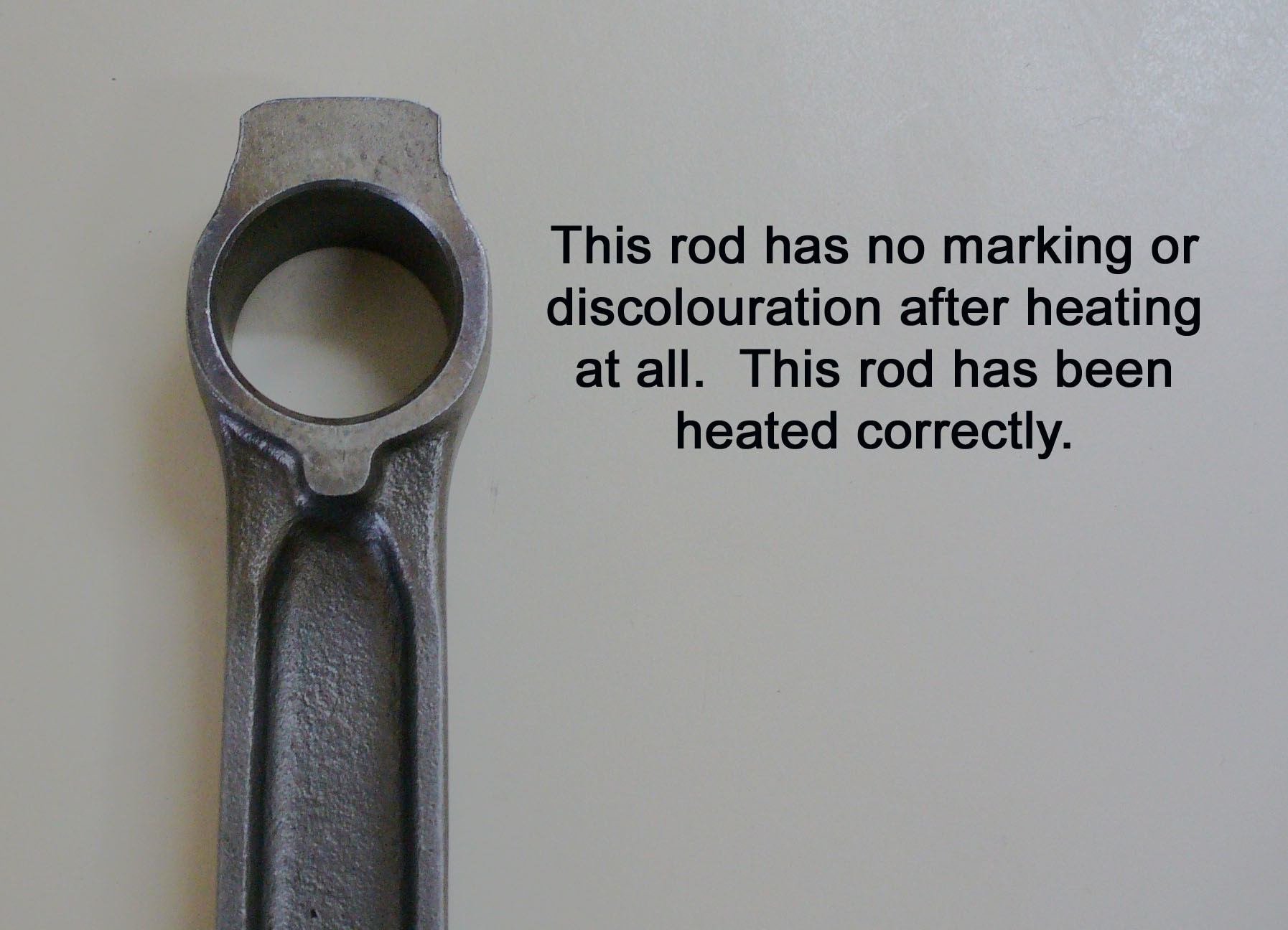

At Galloway Engines, we fit pistons to conrods using a specialised machine. The small end of the conrod is heated by a coiled heating element which is thermostat controlled, to prevent overheating. When the correct temperature is reached, the conrod is immediately fitted to the piston. DON'T RISK ruining the bore of your newly rebuilt / reconditioned engine. Have your pistons professionally fitted to your conrods by Galloways to prevent any future problems. |

|

|